FAQ

The selection of the correct TIR for a specific application is relatively simple. First, select the part number range of the TIRs with the desired contact configuration and rating. TIRs are available in 1 Form C, 1 Form A or 2 Form A contact configurations. Each is available in different contact ratings. For example, if a 1 Form C contact is required to switch 125V at 0.25 amps (31.25 Watts) , the catalog sheet shows that TIR part numbers 6319201 – 6319206 meet this requirement.

Next, select the relay with the highest “Operate Current” rating that is equal to or less than the nominal current for your circuit. For instance, if the circuit has a nominal current of 4.6 amps, in the 6319201 to 6319206 range, P/N 6319202 is appropriate for this application. Because P/N 6319202 has a maximum continuous current rating of 10 amps, there is no danger of damage to the relay coil even if there are large current surges or a sustained current well above the 2.5 amp nominal rating. This selection method is the most conservative because it results in the highest maximum current rating and lowest insertion loss (coil resistance) for the circuit.

A variety of “Special Application” relays are available. Please contact E-MAX for For additional ratings and contact configurations.

E-MAX Type TIR and Type AVR Relays are specialized high-speed electromechanical relays designed for power utility and industrial control applications. They are extremely rugged and are designed for harsh environments.

The TIR and AVR Relays share many physical characteristics; however, they are functionally at two extreme ends of the spectrum of operating features for electromechanical relays.

The Type TIR relays are designed to be connected in series with a current-operated device, such as a lock-out relay coil or circuit breaker coil. They are built with high-current (but meager resistance) coils to be connected in series with the relay or breaker coil and not affect its operation.

The Type AVR relays are designed to be connected in parallel with voltage-operated devices. They are built with very high resistance (but shallow current) coils so that they can be connected in parallel with other voltage-operated devices and not affect their operation.

The terminal studs of all E-MAX Small Relays and Diode Assemblies are made of nickel-plated brass. The recommended torque values are different for the two stud terminal sizes.

The maximum recommended torque for 10-32 size terminal studs is 25.9 inch-lbs.

The maximum recommended torque for 6-32 size terminal studs is 7.9 inch-lbs.

These values coincided with industry standard maximum torque recommendations for the hardware of these types and sizes and tested on these types and sizes and tested on these devices.

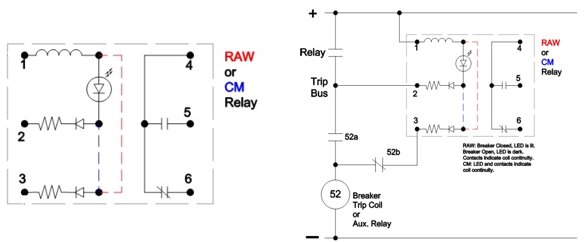

The E-MAX Type RAW (and RAW-1D) and Type CM (and Type CMD) Trip Circuit Monitors are physically and functionally similar. There is one internal connection that changes the operation of the CM, shown in the diagram below:

As the diagram shows, in the Type RAW and RAW-1D relays (red connection), the LED is lit when the relay is energized through Terminals 1 & 2, but bypassed when the relay is energized through Terminals 1 & 3. In the Type CM and CMD relays (blue connection), the LED is lit when the relay is energized through Terminals 1 & 2, or when the relay is energized through Terminals 1 & 3.

This diagram illustrates the difference in operation in a typical application.

Yes, the LEDs are easily field replaceable. Installation Instructions are available by clicking the LED Installation document.

If the DFR clock doesn’t synchronize to a new GPS receiver’s IRIG-B output, there are two possible reasons:

1. The signal output of the new receiver does not match the DFR clock’s configuration;

2. The signal amplitude of the IRIG-B signal from the new receiver is lower than that of the original.

First, to troubleshoot this problem, first verify the signal type (IRIG-B modulated or TTL) now being applied to the DFR. If possible, compare this to the way the old receiver was set. If they do not match, the DFR clock must be reconfigured to accept the new signal. If information regarding the input signal is not available, check the DFR’s configuration to verify that it is correct for the signal now being received. Information on E-MAX DFR clock configuration is available in the system manual, through the E-MAX ShareFile ftp site (available to registered users), or from E-MAX Tech Support.

If the configuration is correct, and the DFR clock still does not sync, it may be due to the signal from the new receiver being of a lower amplitude than the older one. In this case, it may be possible to adjust the clock to increase its sensitivity. Note: This adjustment is available on both the P/N 036D772-773 clock boards, and the 037D651-652 Multifunction Interface Card with IRIG.

To increase the clock’s signal sensitivity, locate the appropriate potentiometer (R39 on P/N 036D772 and 036D773; R15 on P/N 037D651 and 037D752). Adjust this pot to full counterclockwise. Test to verify that the DFR now syncs to the time of the GPS receiver.

E-MAX recorders support several methods of collecting data continuously. The newest continuous form of this in E-MAX recorders is Continuous Waveform Recording. CWR is continuous oscillography and will record all analog and digital inputs continuously, without the need for a specific trigger. CWR data is stored in contiguous one-hour files, and, like other E-MAX data files, uses the IEEE c37.232 COMNAMES file naming standard.

E-MAX recorders can also continuously record phasor data for all analog channels. These files are more compact than CWR files, but can still be used to determine frequency and amplitude, and can provide data necessary for compliance with NERC PRC-002-2 requirements.

In addition to these local continuous recording options, E-MAX recorders can stream data to other devices. All E-MAX DFRs support both IEEE C37.118-2005 and IEC 61850 sampled data protocols through ethernet connections.

E-MAX has several products designed specifically for use in AC systems. The ATR and ATR-D are AC current relays, similar in function to our DC TIR Relays. Both ATR and ATR-D detect AC currents and have solid-state outputs. Type ATR is designed for switching AC loads; Type ATR-D is designed for switching DC loads.

The ACV and ACV-D relays are voltage relays, similar in function to our DC-operated AVRs. They feature the same solid-state output circuitry as the ATR and ATR-D. Type ACV is designed for switching AC loads; Type ACV-D is designed for switching DC loads.

Like the Type TIR and AVR, all of these AC-operated relays feature high-speed operation, wide input ranges, high input/output isolation, and are RoHS-compliant. All E-MAX AC relays are powered exclusively by their inputs, free of any supply power requirements.

While not initially designed for AC operation, the Type RAW-1D is also suitable and recommended for AC applications. The RAW-1D’s delay on drop-out feature allows it to ride through the changes in polarity that occur every half cycle in AC circuits, making it an ideal choice for monitoring AC trip and relay coils.

E-MAX offers support, calibration and service for the SFR-59 series. For SFR-2 series, we offer full service, calibration and support as well as spare parts and assemblies.

We strive to support any and all products of original E-MAX manufacture. Please contact us with any specific requirements.

To view or print the Warranty Policy, click on the E-MAX Warranty Policy document.

All E-MAX brand products are manufactured, serviced, and supported at our facility in Englewood, Colorado, USA. E-MAX does not contract with stocking distributors to supply product. However, we frequently work with several domestic and international distributors and can supply a list of distributor contacts in your area.

We accept MasterCard, Visa and American Express.

E-MAX Instruments

E-MAX Instruments